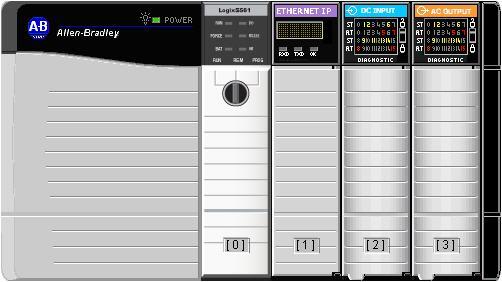

Allen-Bradley ControlLogix PLC / PAC

The ControlLogix family was introduced in 1997. Like its predecessor the PLC-5, this platform was also rack-based, but having much faster scan times and memory than the PLC-5 or SLC products. Communication modules support Ethernet, DeviceNet, DH485, and ControlNet. Of these, only Ethernet, via the EtherNet/IP protocol remains as a viable choice in 2025. Over time, the new Logix programming engine came to embrace the feature set that we now take for granted; object-oriented programming (OOP), text-based symbols, user-defined data types, customisable routines (called Add-On Instructions, or AOI). Program structures were flexible with ‘Cyclic’ and ‘Event-Driven’ tasks added to the traditional ‘Continuous’ task.Significantly, documentation is now stored on the CPU rather than the offline, where it is prone to be lost or subject to version confusion.

In 2000, the little-brother CompactLogix was launched, with the intention of replacing the MicroLogix and SLC-500 families.

ControlLogix is now termed a PAC (Programmable Automation Controller) rather than a PLC (Programmable Logic Controller) to indicate more firmly its capability in the areas of information, process control and motion. Nearly 30 years later in 2025, Allen-Bradley ControlLogix remains the pride of the fleet.

The product has been under constant development since launch, improving performance, features, memory capability, and customisation.

Key features include:

- Structured Data

- Add-on-instructions – custom made code blocks that look and operate just like inbuilt functions. Great for repeated devices like motors and valves.

- Supports 4 of the 5 IEC 61131-3 compliant languages; relay ladder logic, structured text, function block, and SFC languages – Instruction List is not supported.

- Hot swappable IO modules (RIUP)

- Hugely Scalable – up to 128,000 digital; 4,000 analog across multiple chassis, networks and IO types.

- Can be used with all field IO types – Flex IO, Point IO, CompactBlock etc.

- Capability for multiple processors and network cards in-rack.

- Support for full controller redundancy.

The ControlLogix (1756) family is considered a systems processor – capable of distributed / multi-processor control for multi-machine / plant-wide control. Yes, multiple CPUs (and comms modules) may be placed in the 1756 chassis, and in any slot – there are no longer slots reserved for processors or communication adapters.

Current ControlLogix Models

The L7 and L8 families are the current models, with L6 having been discontinued in June 2017.

The L7 boasts double the processing speed of earlier L6 models, however the L7 requires the new Studio 5000 Logix Designer for program development, not the RSLogix 5000 software used to date. Studio 5000 can program all the Logix families of processors.

ControlLogix 5580 Controllers

ControlLogix L8 controllers provide increased performance, capacity, productivity, and security to meet the most demanding applications. Using the Studio 5000 program development environment allows the integration of Motion over EtherNet/IP for high-speed motion applications for up to 256 axes as well as SIL 2/PLd and SIL 3/PLe safety solutions in the safety controller range.

Some other key differentiators between the various models are shown in the following table. (Your device may need to be rotated into landscape view to see this clearly.)

Comparison Table of ControlLogix L6, L7, L8 PAC

| Feature | L6 | L7 | L8 |

| Built-in Port | Serial | USB | Ethernet + USB |

| Energy Storage Module (ESM) Included | No | Yes | Yes |

| Battery Required | Yes | No | No |

| On-board Display Included | No | Yes | Yes |

| Non-volatile Memory | CompactFlash Card | Secure Digital Card | Secure Digital Card (optional) |

L7 is now the entry level processor in the ControlLogix world. It’s a performance machine, for where the complexities of design or magnitude of operations can benefit from the added memory and functions, and huge IO capacity.