CompactLogix Mid-Range PLCs

The Allen-Bradley CompactLogix family of programmable logic controllers (PLCs) from Rockwell Automation provides a comprehensive, scalable solution for industrial automation. This range is ideal for a variety of applications, from small standalone systems to more complex control setups that require robust performance, scalability, and flexibility.

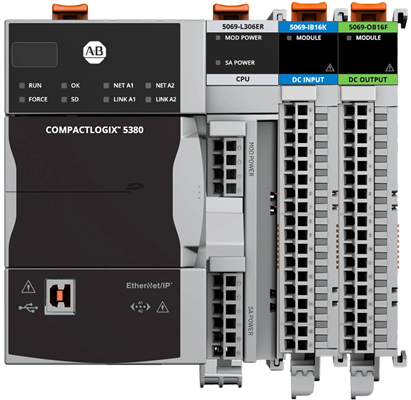

Combined with various IO families, including the relatively new 5069 range, or legacy IO such as PointIO or FlexIO, they provide a solution for new applications, or an upgrade to SLC500 and PLC5 projects. Migration tools take a lot of the work and risk out of these upgrades.

CompactLogix PLCs combine powerful processing capabilities with integrated I/O and motion control, making them suitable for a wide spectrum of industries, including manufacturing, packaging, food and beverage, and mining.

History of CompactLogix

Rockwell Automation’s CompactLogix series of Programmable Logic Controllers has evolved over the years to meet the increasing demands of industrial automation. Below is a chronological overview of the major CompactLogix models, their U.S. launch dates, and the new features introduced with each iteration:

The first CompactLogix controller to be released was the 1769-L20 in late 2000. At the time it was dubbed the CompactLogix 5320, and was joined in 2001 by the 1769-L30 controller, also known as the CompactLogix 5330.

1769-L3x Series (2008)

Introduced in 2008, the 1769-L3x series marked the debut of the CompactLogix line, offering a modular, chassis-free design. These controllers featured integrated communication ports and supported a range of I/O modules, providing a scalable solution for various applications. Intended to be a replacement for larger MicroLogix and SLC-500 based systems, they offered the same Logix engine as the ControlLogix family launched in the same year.

CompactLogix 5370 Series (2012)

Launched in 2012, the 5370 series introduced several enhancements over its predecessors:

- Dual Ethernet ports supporting Device Level Ring (DLR) topologies for increased network resilience.

- Integrated motion control over EtherNet/IP, allowing for synchronized motion applications.

- Enhanced processing capabilities and memory options to support more complex applications.

- Improved security features and support for modern programming environments. The Automation Blog

CompactLogix 5380 Series (2016)

The 5380 series brought further advancements:

- Higher performance with increased processing speed and capacity.

- Support for up to 32 axes of motion control, catering to more demanding applications.

- Enhanced security features, including digitally signed firmware and role-based access control.

- Improved productivity with features designed to reduce commissioning time and ease diagnostics. Rockwell Automation

CompactLogix 5480 Series (2018)

Introduced in 2018, the 5480 series integrated Windows 10 IoT Enterprise alongside the Logix control engine:

- Real-time control combined with the ability to run Windows-based applications, such as analytics and data gathering, directly on the controller.

- Support for embedded Windows applications enables on-machine data collection and decision-making, enhancing the Connected Enterprise.

- Maintained high-performance control capabilities with the added flexibility of an open Windows platform. Rockwell Automation

Each generation of CompactLogix controllers has built upon the strengths of its predecessors, introducing new features and capabilities to meet the evolving needs of industrial automation.

CompactLogix is essentially the replacement for the now out-of-support SLC-500 range, but with considerably more power and functionality.

Overview of the CompactLogix Range

The current CompactLogix range includes the CompactLogix 5370, CompactLogix 5380, and Compact GuardLogix 5380 series, each suited to different performance levels and application demands. These models vary in memory, I/O capacity, processing power, and integrated security features, giving users flexibility in selecting a controller tailored to their system’s requirements.

Key Series in the CompactLogix Range:

- Designed for medium-scale applications that require reliable control at a competitive price point.

- Offers support for local and remote I/O with built-in EtherNet/IP communication, and models with varying memory capacities, but only a single network port.

- Integrated motion support for applications needing fewer axes of motion.

- Suitable for cost-effective, standalone machine control systems.

- Delivers enhanced processing power and higher memory capacity, supporting larger and more complex applications.

- Significantly, this model introduces a second network port, allowing segregation between P2P and dedicated IO networks.

- Improved execution speed (as low as 0.2 µs per instruction) for fast response times in high-speed systems.

- Can handle up to 31 local I/O modules and up to 20 motion axes, making it a strong choice for advanced automation tasks.

- Built-in security features, such as role-based access control, digital signatures, and data encryption, ensure secure operations.

- Integrates both standard and safety control in one unit, reducing the need for separate safety controllers.

- Ideal for safety applications rated to SIL 2 or SIL 3/PLe with integrated safety-rated I/O.

- Offers the same processing power as the standard CompactLogix 5380 models with additional safety functionality, making it suitable for applications requiring both high performance and strict safety compliance.

- Currently the most powerful unit in the range.

- Includes a Windows IoT processor as well as a 5380 Logix engine for fast tight integration.

- Offers 3 network ports for maximum flexibility.

Common Features Across CompactLogix PLCs

- Modular Design: Each CompactLogix PLC supports scalable I/O configurations, allowing expansion as system requirements grow.

- EtherNet/IP Communication: Dual Ethernet ports on most models enable high-speed networking, support Device Level Ring (DLR) topology for redundancy, and simplify integration with other Rockwell Automation products.

- Integrated Motion Control: Select models support coordinated motion control, making CompactLogix ideal for applications requiring precise multi-axis movement, such as robotics and CNC machines.

- Enhanced Security: Role-based security, digital signatures, and data encryption provide robust protection against unauthorized access, safeguarding valuable data and intellectual property.

- Studio 5000 Compatibility: These PLCs are fully compatible with Rockwell’s Studio 5000 software, which simplifies configuration, programming, and integration, reducing setup time and complexity.

Benefits of the CompactLogix Range

The CompactLogix range provides:

- Scalability: Users can select a model that fits their current needs and upgrade easily as their system expands.

- Efficiency: Fast processing speeds and reliable networking enhance system performance and minimize downtime.

- Flexibility: Support for distributed I/O and motion control allows the CompactLogix family to handle complex tasks, while the integrated security features meet modern cybersecurity standards.

- Safety: With the Compact GuardLogix models, users have a built-in safety solution that can meet stringent regulatory requirements.

The Allen-Bradley CompactLogix series offers a versatile automation solution that grows with the demands of industrial applications, from simple machine control to more comprehensive systems that require integrated motion and safety.

Migration from MicroLogix or SLC-500 to CompactLogix

Conversion to CompactLogix from legacy platforms is quite straigtforward.

There are many online resources to explain how to do this, this Migration to CompactLogix video on Youtube is just one of many.

Essentially, the steps are as follows:

- Export comments and database in RSLogix 500

- Save the program as an .ACH form in the same folder as the above exports. This requires V12 of RSLogix 500 (which is the latest available). This will trigger a popup that manages the conversion process.

- The result is a .ACH file that can be opened in RSLogix 5000 / Studio 5000. This whole process takes only about 10 minutes after watching the video and noting the steps to follow.

- Legacy data tables – B3, N7 etc remain as arrays after conversion – tags are not created based on Symbols regretably. So you may need to do some database manipulation to get a meaningfully documented project.

- If you have AOI for drives and valves etc, you will probably not be happy with a rstraightforward ung by rung conversion. So you will then need to allow some time for adding in AOI, and mapping the IO, interlocks and permissives etc into the AOI to truly exploit the functionality of the new CPU.

If you don’t have time to do this, there are many system integrators available – we recommend ATS Applied Tech Systems (1300 468 288) who have offices throughtout Victoria and also in NSW, but there are many others. We will get around to creating a list eventually!